Model-Based Design and the Model-Based Enterprise

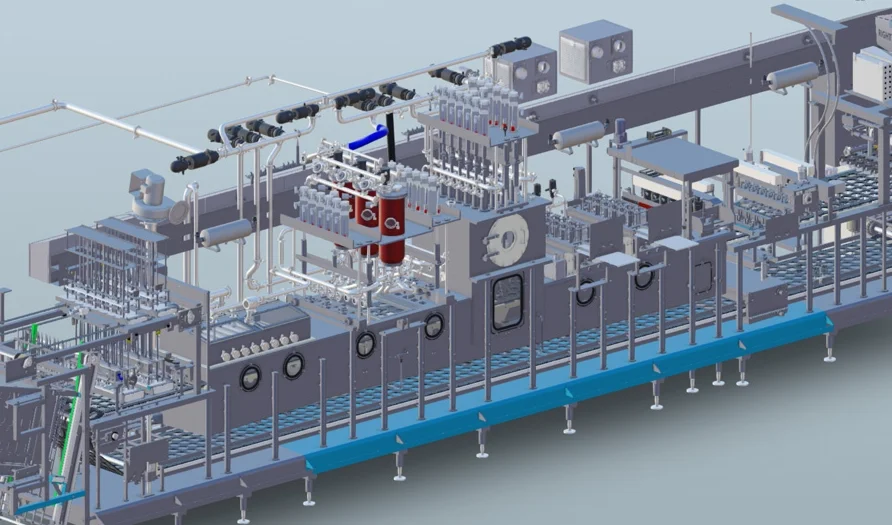

/What manufacturing company hasn't faced unnecessary rework, confusion on the shop floor and thus missed delivery dates? The cause can repeatedly be traced to unclear, ambiguous documentation often found in 2D drawings. Help is at hand, fortunately. An evolving solution for authoring product definition and design intent, sourced at the CAD models, is gaining recognition.

Read More